IT/OT convergence, Industry 4.0, and increased digitalization all shape the way the production floor connects and interacts with IT. This interconnectivity makes it crucial to have a central overview of your entire infrastructure.

Traditionally, classic IT networks were monitored separately from OT components, if the OT was monitored at all. Because of the increased digitalization and connectivity of OT environments, however, keeping an eye on both IT and OT becomes more and more important. So why should you monitor industrial IT?

Previously segregated teams now rely on each other. For example: IT teams are responsible for ensuring that the data generated by machines on the factory floor makes its way to the cloud, while industrial engineers or managers might need access to that data to make decisions regarding the production line or to implement predictive maintenance strategies. All teams need to work from the same data, but they need different views of it.

Because data flows through several systems, all gears need to work flawlessly together: if one doesn’t work, other processes will be impacted, too. If a failure occurs, a simple alert to troubleshoot the issue is not enough. Teams need to understand the root cause of a problem to prevent it from happening in the future. But to find the root cause, teams need to look across systems and interfaces.

Digitalization has made it vital to be able to generate and analyze insights using data from all parts of the enterprise. Data created on the factory floor must be aggregated and sent to upstream on-premises or cloud systems for processing. Because this data travels across OT and IT networks, it’s essential to monitor that it flows correctly through various interfaces and touchpoints in the infrastructure.

Do you want to have a full overview of your OT environment in your supervisory and control systems – including traditional IT network components like routers, switches, firewalls, and more?

PRTG OPC UA Server consolidates monitoring data from your OT network and the IIoT in your control system. View all your data in one place for centralized monitoring and alarms.

Diagnose issues with your industrial IT infrastructure by continuously monitoring your industrial devices, edge computing environment, IT hardware, applications, and more. Show monitoring data in real time and visualize it in graphic maps & dashboards to identify problems more easily. Gain the visibility you need to troubleshoot issues before they become critical.

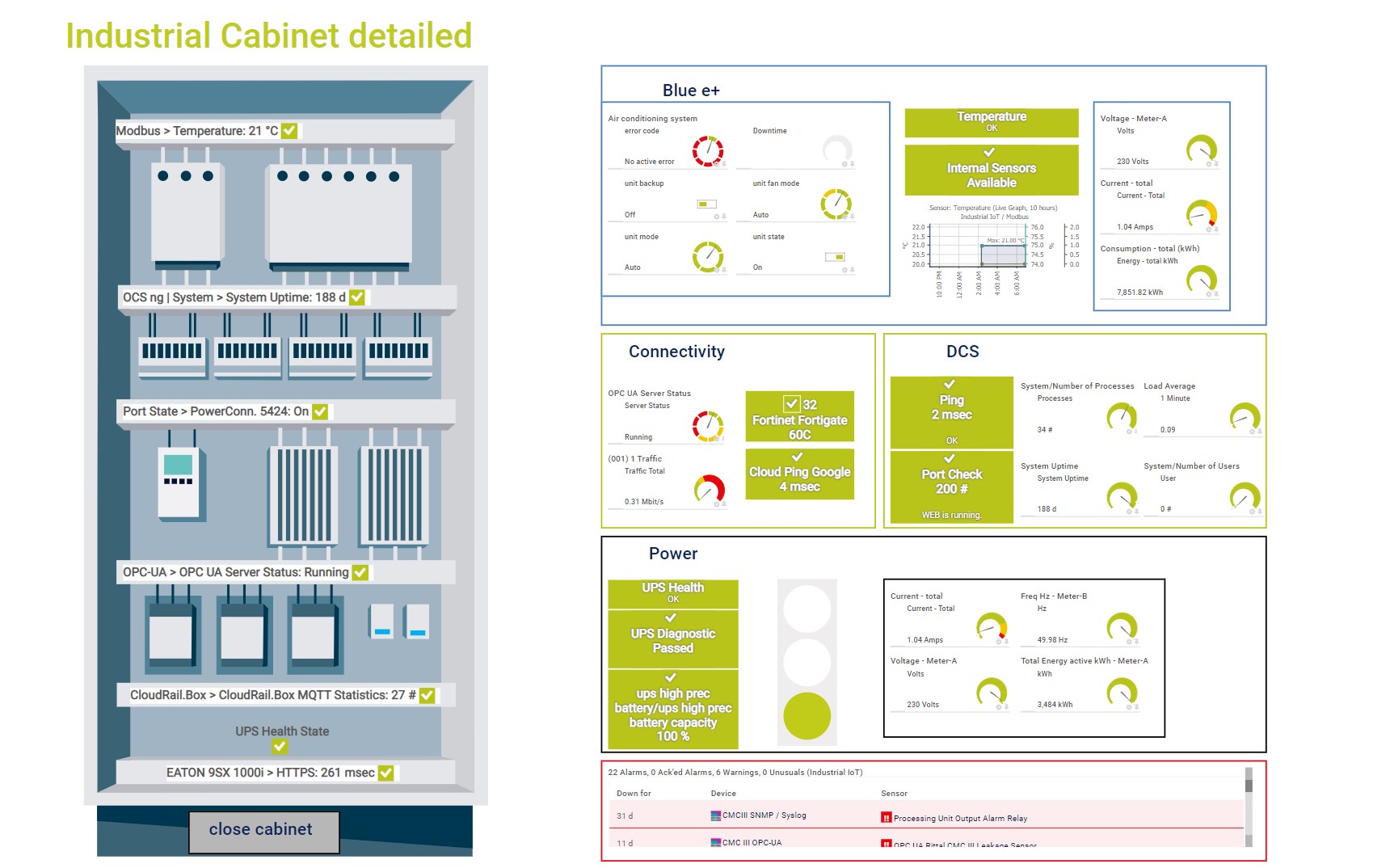

PRTG dashboard for monitoring an industrial cabinet

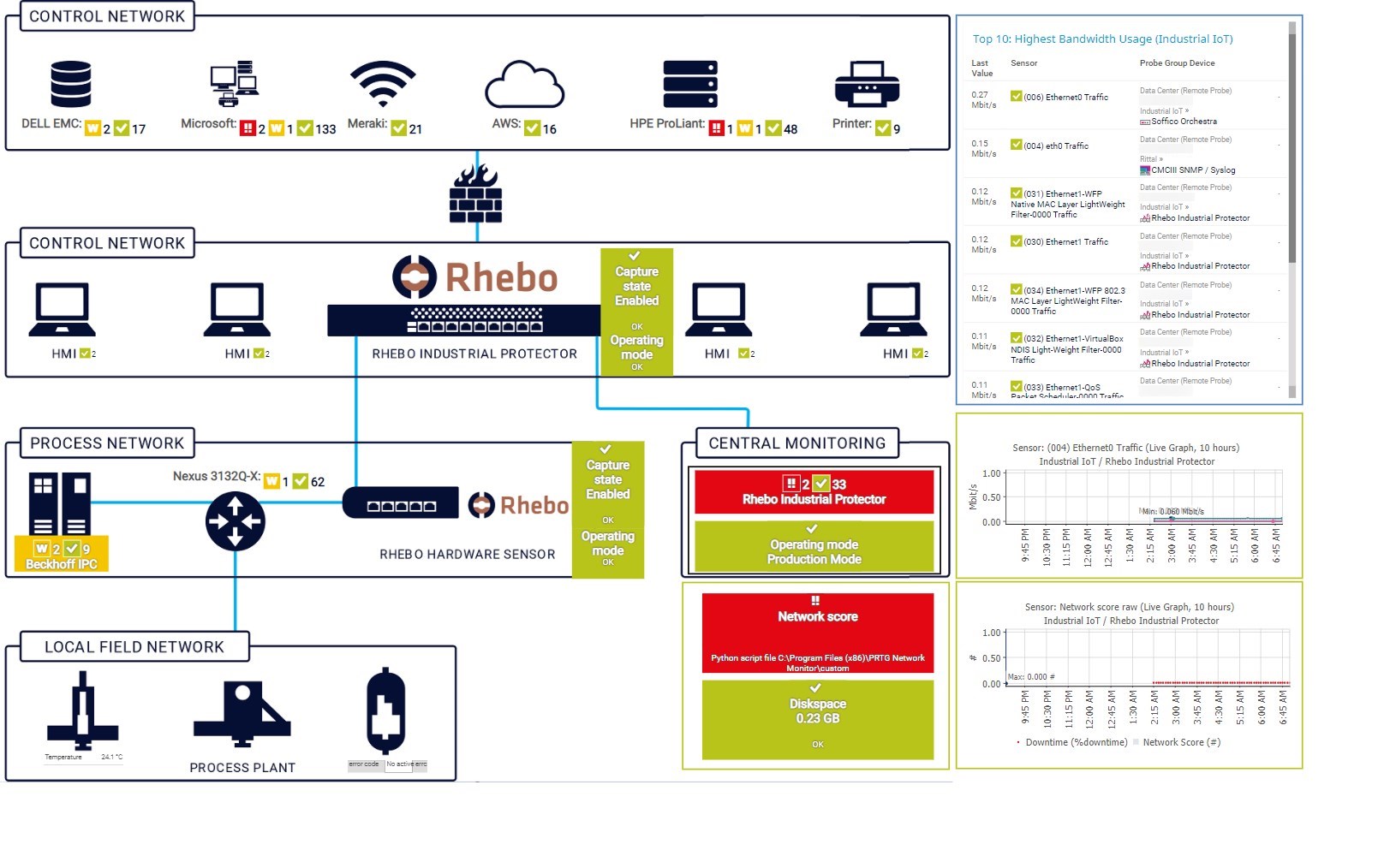

Custom PRTG map for visualizing Rhebo integration & monitoring

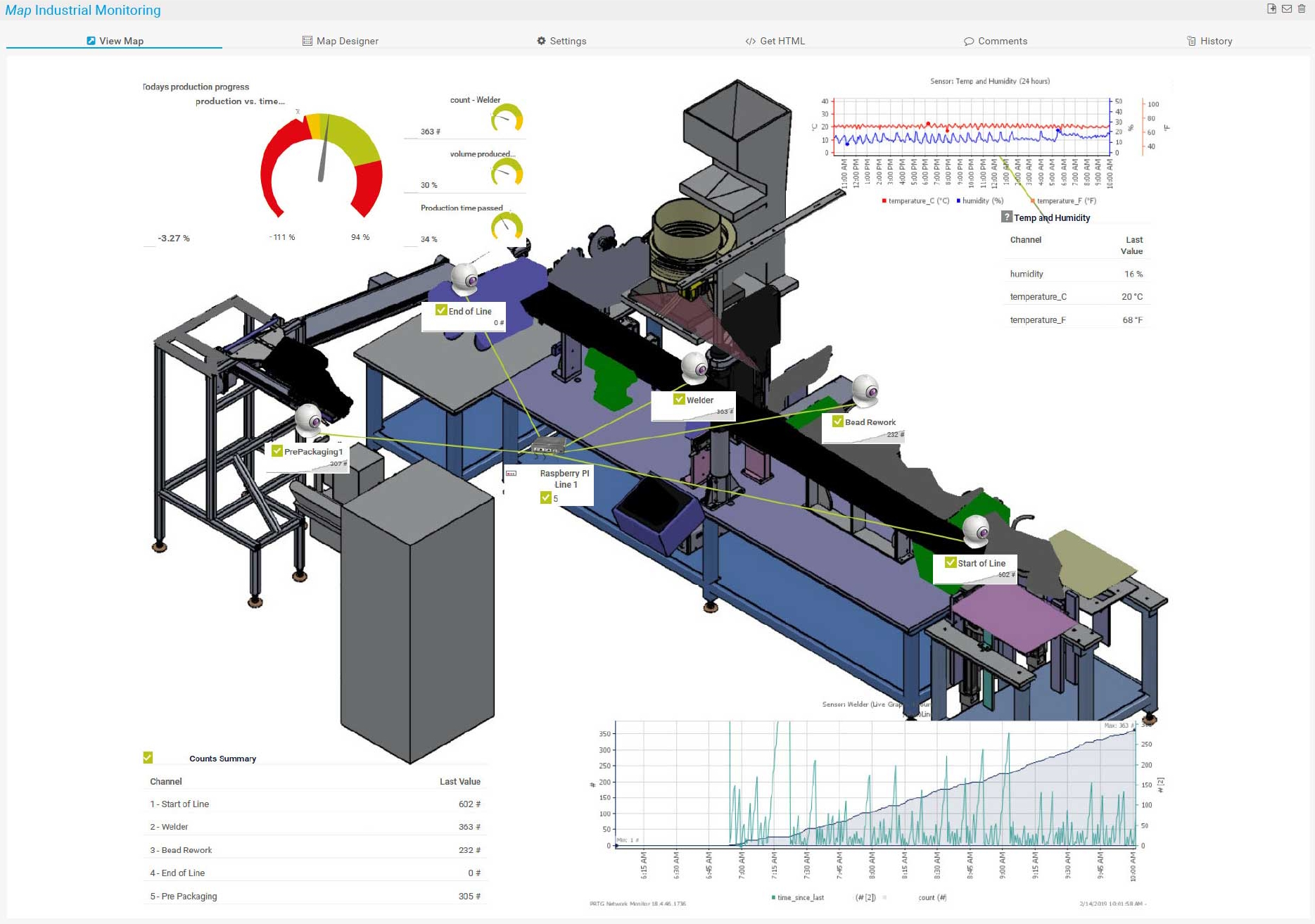

Keeping an eye on your production line with PRTG

“Great interface, intuitive, full REST support. custom scripts, rest sensors add extra value. We have been using PRTG for 10 years now in multiple environments and use cases. it has by far the best interface and very easy to setup without prior experience.”

In modern, digitalized industrial environments, the worlds of IT and OT are interconnected. This includes programmable logic controllers, industrial PCs, smart industrial gateways, and IoT sensor technology, as well as traditional IT infrastructure components like network switches, routers, and wireless components.

Read our brochure about industrial IT monitoring with PRTG and find out how you can bring your IT and OT environments together in a single view.

Beyond out-of-the-box integrations for all classic IT standards, PRTG offers a REST API as well as

JSON, OPC UA, Modbus, and MQTT support. Easily integrate OT components, IoT hardware sensors, as well as IT devices and applications with our preconfigured PRTG sensors.

See the PRTG Manual for a list of all available sensor types.

In modern industrial IT, the right teams need the right data. Our guide shows how to implement holistic monitoring that brings elements from IT, OT and IIoT into your dashboards.

Our second guide gives you inspiration and ideas for dashboards that feature IT, OT and IIoT data – all in one place. We show you what truly convergent industrial dashboards look like!

Companies around the world trust PRTG Network Monitor when it comes to ensuring that their IT systems run smoothly.

F.T.P. has 20 years of experience providing IT consulting to the most established automotive companies in Italy’s Motor Valley. System integration, cyber security, managed services, and industrial technology are their main areas of expertise. From a strong focus on the enterprise environment to the world of SMEs: F.T.P. offers high-value monitoring services through PRTG and enters new markets, including OT.

SMS group GmbH provides production plants for the steel industry worldwide that rely on modern control technology as well as automation systems with corresponding real-time networks. The company uses PRTG to ensure performance and reliability during the construction, testing, and start-up of metallurgical plants (steel production plants), and thereby optimizes the quality of its production lines.

Siemens AG is a German corporation that focuses on industrial automation and digitalization, building infrastructure, distributed energy systems, rail and road mobility, and medical technology. Its Industrial Automation DataCenter (IADC) is an individually configured data center for on-site use in manufacturing. PRTG monitors all components of the IADC, providing a comprehensive overview.

Industrial IT refers to the application of modern information and communication technologies in industrial processes and manufacturing environments. It involves the integration of various IT systems, software, and hardware components to optimize and automate industrial operations, enhance productivity, increase efficiency, and improve overall business performance.

The goal of industrial IT is to create a more interconnected, data-driven, and efficient industrial environment. It can be applied across various industries, including manufacturing, energy, transportation, healthcare, agriculture, and more.

The integration of technology into industrial processes can lead to cost savings, improved product quality, increased safety, reduced downtime, and better utilization of resources.

Industrial IT monitoring plays a crucial role in maintaining and optimizing the performance of industrial processes, systems, and equipment. It involves the continuous collection, analysis, and visualization of data from various sources within an industrial environment.

The primary purpose of industrial IT monitoring is to ensure that operations are running smoothly, identify potential issues or anomalies, and enable timely intervention to prevent disruptions.

Industrial IT monitoring is also a proactive approach to managing industrial processes and equipment. It enables companies to enhance efficiency, reduce downtime, increase product quality, and maintain a competitive edge by leveraging real-time data and insights for continuous improvement.

IT/OT convergence, referring to the integration of Information Technology (IT) and Operational Technology (OT) systems, offers several compelling benefits for organizations in various industries. Here are some reasons why you should consider IT/OT convergence:

An industrial IT monitoring tool like Paessler PRTG can provide you with a range of benefits:

In PRTG, “sensors” are the basic monitoring elements. One sensor usually monitors one measured value in your network, for example the traffic of a switch port, the CPU load of a server, or the free space on a disk drive. On average, you need about 5-10 sensors per device or one sensor per switch port.

Read about how a biological scientist with an IT background and an IT network administrator built an inexpensive yet powerful production monitoring system with PRTG and simple sensors connected to a Raspberry PI.

Watch this free webinar to get an overview of our PRTG sensors for industrial IT (MQTT, Modbus, OPC UA, and more). In addition, we’ll show you use cases to demonstrate how these sensors can help you master your daily challenges in IT and OT monitoring.

For more insights into and information about PRTG in the industrial sector, have a look at our industrial resource center page. Find out about use cases, industrial IT knowledge, industrial alliances, and Paessler-recommended industrial IT partners.